Product Inspection using NI Smart Camera

It is important to ensure that all components in an electrical system are properly installed and functioning. One key aspect of this is the quality of wire connectors, which are critical for establishing reliable electrical connections. To ensure the quality of these connections, This project visually inspects wire connectors using various imaging techniques. By using image processing and computer vision, it is possible to detect and identify common issues that can impact the performance of wire connectors, such as poor crimping or misaligned wires. Catching these issues early, can help to ensure that electrical systems operate reliably and efficiently.

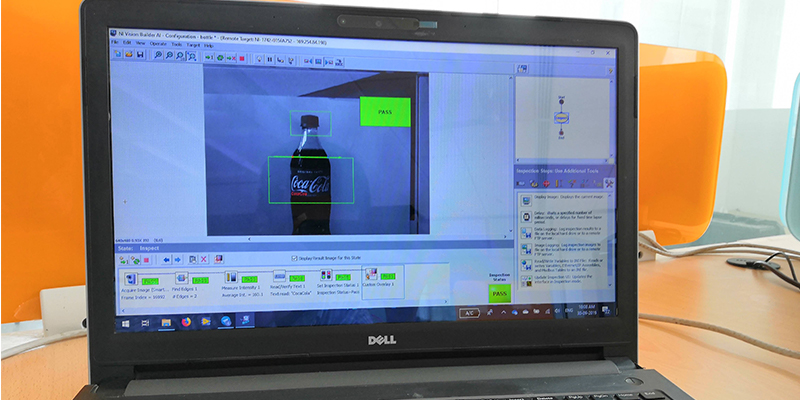

This project was aimed at developing an end-of-line testing system that would ensure that no defective parts leave the manufacturing line of a company. To achieve this, I designed a visual inspection system that identifies and removes any defective products from the production line. For this purpose, I utilized NI Smart Camera, cRIO, and NI Vision Builder AI to create an automated system that can perform real-time image processing and analysis of products on the manufacturing line. With this system, companies can be confident in the quality of their products, and customers can be sure that they are receiving high-quality items.